Bringing the Benefits of the Digital Oilfield to Water Management

Where is all the water going? As much as 10 barrels of saltwater is produced for every barrel of oil in the Delaware Basin while the Midland Basin averages a mere three barrels of saltwater. Water cut varies from basin to basin but, with the Permian dominating oil production, that means that wells in west Texas and southeastern New Mexico produce a staggering volume of saltwater every day. And think of the large-scale hydraulic fracturing activity and the flow back involved. Let’s discuss water management and how digital transformation is helping service providers efficiently track, move, and dispose of produced water.

The Permian oil boom of the last decade simultaneously triggered a boom for water management. What had been largely manageable with a focus on Midland drilling and production suddenly became unmanageable at the scale of water cut in the Delaware. The initial response has been to throw trucks at the problem, adding to the already intense traffic around the basin. However, just as gathering, transportation, and storage have caught up with major oil infrastructure bottlenecks, water management infrastructure is rapidly being built out. Where the water is headed is also evolving. The majority of produced saltwater is trucked or piped to disposal wells for injection; however, new technologies and business models are recycling saltwater for hydraulic fracturing, irrigation, and potentially for agricultural use. West Texas might look greener in the near future.

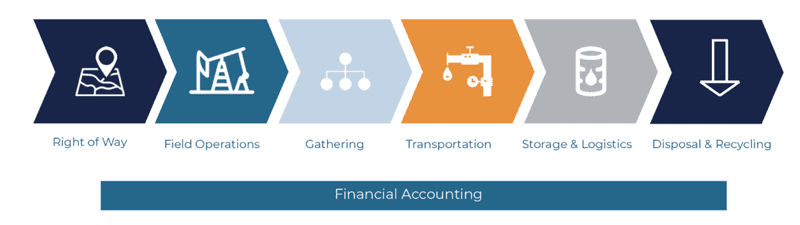

Water management is a crucial and rapidly growing link in the energy value chain, giving rise to highly specialized midstream companies. Water management service providers also resemble upstream operators in many ways. Both own, operate, and maintain wells, albeit shallower injection wells on the waterside. Operators and water management service providers must also track produced volumes, monitor production trends, prevent well downtime, and respond to issues in the field. As a midstream company, these service providers also share common business challenges with companies that gather, transport, and store oil. They share similar needs to attract and compete for contracts, accurately perform accounting and invoicing, and manage right of way ahead of planned infrastructure.

What water management service providers do not share in common with upstream and midstream companies is the same level of innovation and the benefits of the digital oilfield. For decades, producers and oil and gas midstream service providers have applied information technology to drive their core business, whether that’s finding reserves, drilling, optimizing production, gas processing, or moving hydrocarbons. Digital oilfield innovation has brought new operational and cost efficiency to these companies. Water management has largely been underserved by technology providers, but the need for efficiency gains is just as vital, a problem that has been brought into sharp focus as the water management sector expands.

Digital Transformation for Water Management Field Operations

Oil and gas producers pay to have produced saltwater hauled from well sites, whether that’s by truck or pipeline. With nearly 400 operators in the Permian Basin alone and thousands of producers across the U.S., water haulers compete for business every day. Fees can be a deciding factor, so anything service providers can do to lower their costs is a competitive advantage. These companies must also precisely track water volumes and respond to trends in their markets, such as declining water volumes that indicate business is falling off and where to focus sales efforts.

Impeding all of this are information delays between the field and back-office. Pumpers make daily rounds on their well routes to maintain water tanks, skim oil from the surface, and record water haul transactions, among other tasks. Paper-based run tickets are often collated into a spreadsheet by week’s end before being e-mailed to the back office. Water management also relies on automated field data capture (SCADA) for gathering and pipelines. But the end products from people and automated systems are too often a spreadsheet, which has to be manually aggregated, reconciled, and formatted to provide an overarching, operational view. It’s time-consuming, error-prone, and delays tactical decisions.

Solving the field data management problem starts by bringing scattered sets of field operations data together in one, validated information hub. Mobile field data capture applications help field operators record and validate water volumes and other data directly on their phone, tablet, or laptop instead of a paper or spreadsheet. Cloud-based field data capture solutions also support the integration of SCADA data in real-time, providing water management service providers with up-to-date and accurate field information.

The cloud also provides seamless reporting and analysis on any device with a web browser. Such solutions can be rapidly tailored to each service provider’s business needs and key performance indicators to build a precise operational view. At a glance, the cloud-based water disposal dashboard gives field operations staff and management a clear view of trends over time, enabling business development to respond to market decline, adjust capacity to meet customer growth, and take proactive steps to prevent equipment failure and well downtime.

Cloud-based water management solutions equip service providers with a centralized and quality-controlled system of record in which to track volumes, run tickets, and injection wells. In addition to quick look analysis and daily field operations reporting, data warehouses can be securely accessed by API. As a result, users can directly access field operations data using SQL or business intelligence (BI) analysis software.

One Digital Water Management Solution, Upstream to Midstream

Water management service providers face many complexities in managing daily operations and growth. Increasing emphasis is being placed on a dedicated gathering and transportation pipeline infrastructure to accommodate record amounts of produced water in basins across the country. Just as oil and natural gas infrastructure requires extensive planning to secure required acreage for future infrastructure, water management companies must obtain land and environmental rights to construct gathering and transportation systems to carry away saltwater from well sites to storage facilities and disposal wells. All of this presents a highly complex logistical challenge to orchestrate the physical movement of water through the system and an accounting challenge to efficiently manage contracts and fee structures, settle monthly transactions, invoice producers, and cut checks to vendors.

There are a lot of moving parts to produced saltwater disposal operations. Out of necessity, service providers resort to multiple pieces of accounting, planning, and reporting software with many spreadsheet-based solutions and workarounds. The problem is that all of these point solutions are all too often built with different technologies at different times for widely varying purposes. The result is data silos, systems that cannot exchange data, and high total cost of owning software. Such software includes revenue accounting, financial accounting (AP, AR), cost accounting, land management, contract management, water transportation, terminal management, and scheduling. There are also G&A and opportunity costs, not to mention the frustration of having staff spend significant time shuffling data between software systems to settle the month.

The cloud offers a focal point on which to build a fully unified enterprise resource planning (ERP) solution, seamlessly bringing together field operations, accounting, gathering, storage, pipeline logistics, and land workflows. This provides water management service providers with multiple benefits, including dramatically lower software costs, lower G&A, and operational efficiencies. It also empowers the back office with one solution to manage core business functions, enabling staff to focus on high-value tasks and helping service providers accelerate business performance and navigate market complexities. But more than that, a unified ERP solution that solves water management challenges creates new opportunities to pass on those performance gains and cost efficiencies to customers, enabling service providers to compete and win producer contracts in an increasingly competitive space.

Produced water transportation and disposal service providers are turning to W Energy Software’s Midstream ERP and Field Operations platform to manage their business. It provides service providers with a unified water management solution to improve business performance, adapt to evolving market conditions, and reduce costs. The need for effective and efficient methods of managing produced water will increase in urgency as U.S. oil production resumes a strong growth profile. And, as the oilfield water management sector expands, the new levels of efficiency, agility, and competitiveness that can be unlocked are especially well-timed.